Innovations and Trends for Construction, Manufacturing, Government, and Military Operations

As we step into 2026, the landscape of industrial safety is evolving rapidly, with advanced gas detection monitors for 2026 workplace safety leading the charge. These monitors protect workers from invisible threats like carbon monoxide, hydrogen sulfide, and volatile organic compounds. At Apollo Safety, we’re at the forefront of this transformation. We offer state-of-the-art monitors that integrate cutting-edge technology to meet the demands of high-risk environments. This post explores the historical roots of gas detection, its progression to today’s sophisticated systems, and the exciting trends shaping 2026. It also highlights how our products empower businesses, governments, and military units to enhance operational resilience and compliance.

The History of Gas Detection: Foundations for Advanced Gas Detection Monitors

Gas detection monitors have humble beginnings rooted in the early days of mining and industrial work. In the early days, the absence of reliable detection led to countless tragedies. The story starts in the 19th century with the canary in the coal mine. A live bird used to detect toxic gases like methane and carbon monoxide, as its sensitivity would cause it to falter before humans were affected. In 1815, Sir Humphry Davy invented the flame safety lamp, also known as the Davy lamp. The Davy lamp not only illuminated dark mines, but also indicated the presence of flammable gases by altering the flame’s behavior, marking one of the first mechanical detectors.

By the early 20th century, innovations accelerated. In the 1920s, Dr. Oliver Johnson at Standard Oil developed the first combustible gas monitor using catalytic combustion technology, a breakthrough that allowed for more precise detection of explosive vapors. The 1970s brought electronic sensors into play, enabling continuous monitoring of ambient air for multiple gases. These milestones laid the groundwork for the wireless, AI-integrated devices we see today, transforming reactive safety measures into proactive ones. At Apollo Safety, our monitors build on this legacy, ensuring that historical lessons inform modern reliability for sectors like government infrastructure and military deployments.

Evolution to Today’s Advanced Systems: Building Advanced Gas Detection Monitors

Advanced gas detection monitors owe their sophistication to decades of technological refinement, shifting from basic analog devices to digital, interconnected ecosystems. Post-World War II, electrochemical sensors emerged, allowing for the detection of toxic gases at low concentrations. This was crucial during the industrial boom. The 1980s introduced portable monitors with digital displays and alarms, making personal safety more accessible.

The turn of the millennium saw the integration of photoionization detectors (PIDs) for volatile organic compounds (VOCs) and infrared sensors for combustible gases. These advances enhanced the accuracy in diverse environments. Wireless connectivity and data logging became standard in the 2010s, enabling real-time alerts and predictive analytics. Today, these evolutions manifest in rugged, user-friendly devices that comply with stringent standards like UL/CSA. Apollo Safety’s lineup, such as the Industrial Scientific Ventis Pro5 with LENS wireless technology, exemplifies this progress. These monitors provide seamless integration for manufacturing plants and military operations where rapid response is critical.

2026 Trends in Gas Detection: Shaping Advanced Gas Detection Monitors for Workplace Safety

Advanced gas detection monitors are set to be revolutionized by emerging trends like IoT integration, AI-driven analytics, and sustainable designs, as the global market surges forward. According to industry forecasts, the portable gas detector market is projected to grow from USD 3 billion in 2026 to USD 5.2 billion by 2035. These numbers are driven by stricter regulations and technological adoption. Smart systems with cloud connectivity will dominate, allowing for remote monitoring and predictive maintenance to preempt hazards.

AI and machine learning will enhance anomaly detection, while eco-friendly sensors reduce environmental impact. Wireless and wearable tech will expand, particularly in confined spaces, with a focus on interoperability for large-scale operations. For businesses and governments, this means lower costs through rentals and bundles; military applications will benefit from rugged, encrypted devices. Apollo Safety is aligning with these trends by offering monitors like the Radius BZ1 Area Monitor with LENS Wireless. The Radius BZ1 is ready for 2026’s demands in construction sites and manufacturing facilities.

Real-World Applications: Advanced Gas Detection Monitors for 2026 Workplace Safety in Action

Advanced gas detection monitors shine in practical scenarios, where they avert disasters through timely interventions. For instance, in a Middle Eastern oil refinery, a sudden spike in hydrogen sulfide (H2S) levels was detected by a wireless gas monitoring system. The detection triggered immediate alarms that enabled the emergency response team to evacuate the area swiftly. The quick response prevented exposure or a larger catastrophe. This underscores the value for manufacturing facilities and military contractors handling volatile materials, where multi-gas monitors like Apollo Safety’s Industrial Scientific VentisPro5 (available at VentisPro5) provide real-time wireless alerts for gasses including H2S, ensuring rapid response in high-stake environments.

Similarly, at a chemical plant, a small chlorine gas leak during routine operations was identified early by the installed gas detection system. The detection activated alarms and prompted immediate investigation and repair. The prompt reaction helped with preventing any health issues and avoiding a potential escalation into a major incident. Government-funded infrastructure projects, like tunnel construction, benefit from single-gas monitors to identify oxygen deficiency, as seen in systems that prevent hypoxia by providing early warnings during drilling or excavation. Apollo Safety’s Tango TX1 for HCN, with dual-sensor redundancy (available at Tango TX1 HCN), is ideal for such confined spaces.

Another manufacturing example involved an ammonia leak at a cold storage facility in Virginia in 2024. During this incident, gas detection system detected rising levels, leading to quick evacuation and emergency response. This quick detection minimized harm to workers despite 33 hospitalizations. For broader coverage, area monitors like the Radius BZ1 (at Radius BZ1) can prevent harm. These monitors can prompt excavation by offering wide-zone detection.

The Imperative for Adoption: Latest Statistics and Mitigation with Advanced Gas Detection Monitors for 2026

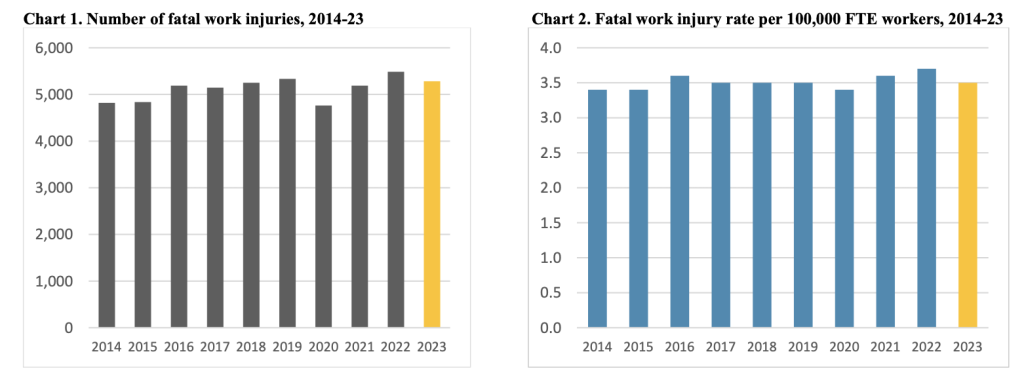

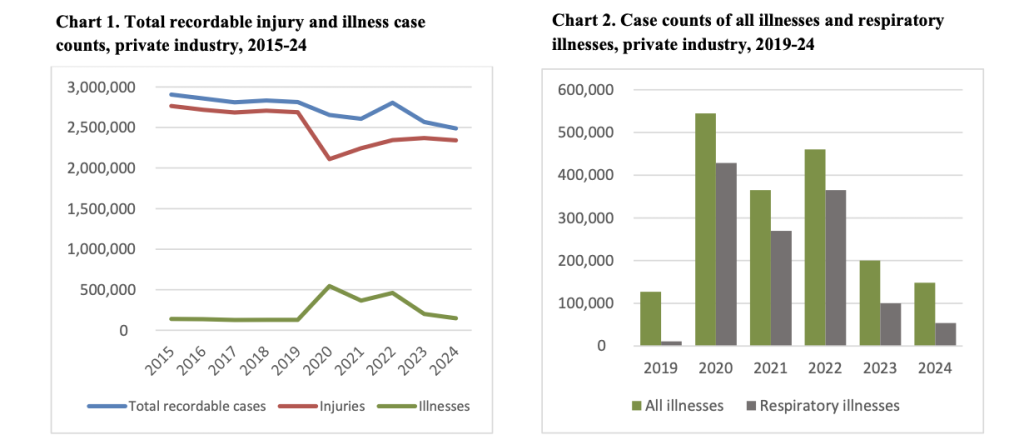

Advanced gas detection monitors become even more critical when viewed against recent statistics on workplace hazards. These findings emphasize the need for proactive mitigation. The U.S. Bureau of Labor Statistics reported 820 fatal work injuries in 2023 due to exposure to harmful substances, including toxic gases, with nonfatal cases exceeding 650,000 in prior years.

In the oil and gas sector, explosions and chemical exposures led to rising fatalities, with 29 deaths from explosions alone in recent reports. Construction and manufacturing account for a significant portion, with hazardous chemical exposures affecting 22.9% of construction workers weekly in 2024.

These figures highlight the urgency, but advanced monitors from Apollo Safety turn the tide by enabling early detection and response. For instance, our Ventis MX4 Multi-Gas Monitor (at Ventis MX4) mitigates risks in IDLH environments. Rentals offer flexible solutions for government projects, directly addressing these stats through bundled protective gear.

Spotlight on Apollo Safety Products: Advanced Gas Detection Monitors for 2026

Advanced gas detection monitors at Apollo Safety include a comprehensive range of specialized devices tailored for precision, durability, and user-friendly operation across various industries. Our selection features leading brands like Industrial Scientific, RKI, and RAE Systems, with options for purchase, rental, and bundling to suit budgets and project scales. Below, we delve into specific categories and highlight key products, emphasizing their features, applications, and how they align with 2026’s safety trends. Explore our full catalog at Gas Detection Equipment. We offer discounts on bundles and free expert calibration to prepare for the year ahead.

Single-Gas Monitors: Advanced Gas Detection Monitors

Advanced gas detection monitors in the single-gas category focus on targeted, reliable detection for specific hazards. Single-gas detection monitors are ideal for personal protection in confined spaces or routine checks. These compact units are designed for long-term use without frequent maintenance, featuring IP-rated durability and intuitive alarms.

One standout is the Tango TX1 Single-Gas Monitor for HCN (available at Tango TX1 HCN). This single-gas monitor utilizes dual-sensor technology for redundancy, ensuring no false negatives even in harsh conditions. With up to three years of continuous operation on a single battery, IP67 water and dust resistance, and audible/visual/vibrating alarms, it’s perfect for manufacturing environments handling cyanide compounds or military operations in chemical-threat zones. Priced competitively, it includes data logging for compliance reporting, helping reduce exposure risks as per recent BLS data.

Another essential offering is the RKI CO-04 Carbon Monoxide Single-Gas Personal Monitor (at RKI CO-04), boasting an impressive 9,000-hour battery life and field-replaceable sensors for minimal downtime. Its lightweight design (under 3 ounces) and clip-on convenience make it a favorite for construction workers in engine-heavy sites or government infrastructure projects, where CO buildup from generators is a common threat. Key features include peak value display and STEL/TWA alarms, aligning with OSHA standards for 2026 updates.

Bundle these with accessories like bump test kits for discounted rates, enhancing portability and readiness.

Multi-Gas Monitors: Advanced Gas Detection Monitors

Advanced gas detection monitors extend to multi-gas models, which simultaneously detect multiple threats like LEL, O2, CO, and H2S. Multi-gas monitors provide versatile protection for dynamic job sites. These devices incorporate wireless tech for team-wide alerts, making them indispensable for collaborative operations.

The Industrial Scientific Ventis Pro5 (at Ventis Pro5) detects up to five gases with LENS Wireless connectivity, allowing real-time data sharing across devices. Its extended Li-ion battery supports over 18 hours of runtime, and features like man-down alarms and customizable sensors. Ruggedized for drops up to 2 meters, it also offers iAssign technology for user tracking.

Complementing this is the Ventis MX4 Multi-Gas Monitor (at Ventis MX4). The Ventis MX4 is configured for CH4 (0-5%), CO, H2S, and O2, with a black housing for low-profile use. It includes data logging for 500 events and IP66/67 rating, suitable for wet construction environments or government tunnel works. For rentals, our AS-RNT-MGD4 Four-Gas Detector Monthly Rental (at AS-RNT-MGD4) provides a cost-effective option at $75/month, covering calibration and maintenance. It’s the perfect monitor for short-term projects.

Opt for bundles with protective cases to boost conversions and ensure compliance in 2026’s IoT-driven landscapes.

PID Monitors: Advanced Gas Detection Monitors

Advanced gas detection monitors include PID-equipped devices for detecting volatile organic compounds at low levels, crucial for chemical-heavy industries. These integrate high-sensitivity sensors with multi-gas capabilities for broad-spectrum monitoring.

The Industrial Scientific MX6 iBrid Multi-Gas Monitor (at MX6 iBrid) combines LEL (IR-CH4), NH3, H2, O2, and PID sensors, offering a full-color LCD and data logging for up to 1,000 events. Its PID detects VOCs down to ppb levels, making it essential for decontamination ops, where solvent vapors pose risks. With benzene-specific mode and wireless options, it addresses emerging AI analytics trends.

Monitors can be bundled with dehumidifier tubes for enhanced performance in humid 2026 environments.

Area Monitors: Advanced Gas Detection Monitors

Advanced gas detection monitors feature area monitors for perimeter surveillance, providing wide-area coverage with loud alarms and wireless integration.

The Radius BZ1 Area Monitor (at Radius BZ1) detects LEL (Pentane), CO, H2S, O2, and SO2, with a pump and up to 7 days of runtime. Its 108 dB alarm and LENS Wireless enable group notifications, ideal for large manufacturing warehouses or military base perimeters. Weatherproof and deployable in minutes, it prevents mass exposures as seen in past BLS reports.

Bundle with solar power options for extended outdoor use in construction zones.

Fixed Gas Monitors: Advanced Gas Detection Monitors

Advanced gas detection monitors also encompass fixed systems for continuous facility monitoring, with explosion-proof designs and multi-channel capabilities.

Our range includes the 35-3001 Series for various gases, such as the 35-3001 for Combustibles 100% LEL / Carbon Monoxide 0-300 ppm (at 35-3001 Combustibles/CO), featuring sample draw detection and transmitter options. It’s suited for stationary manufacturing setups.

The RM-5000 Series offers multi-channel housings, like the 10-Channel Panel Mounting (at RM-5000 10-Channel), at $2,025, for scalable government facilities.

IR models, such as the 35-3001 for IR Carbon Dioxide 0-5% (at 35-3001 IR CO2), provide non-dispersive infrared sensing for accurate, low-maintenance operation.

These fixed units integrate with control systems, bundling with calibration for comprehensive 2026 compliance.

In wrapping up, advanced gas detection monitors represent a fusion of historical wisdom and futuristic innovation. These monitors are poised to redefine protection in construction, manufacturing, government, and military spheres. Apollo Safety invites you to partner with us for customized solutions that prioritize your team’s well-being. Contact us today for consultations and secure your operations for the year ahead.