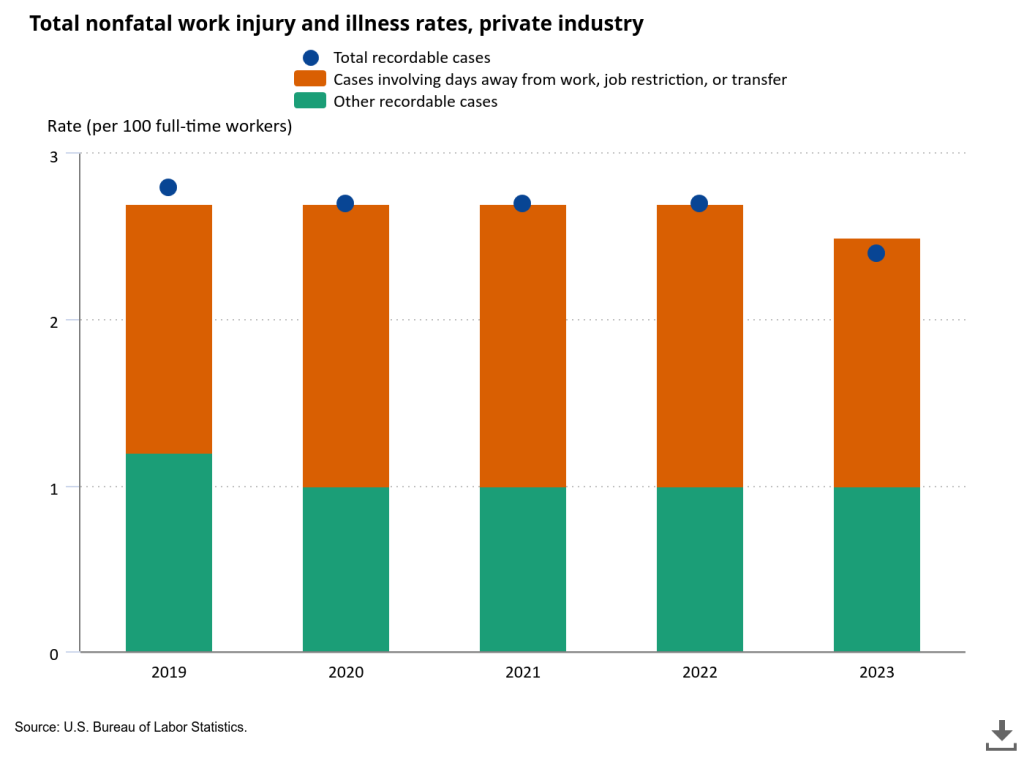

In today’s demanding work environments, ensuring the safety of personnel is paramount, especially in high-risk sectors like construction, manufacturing, government infrastructure projects, and military operations. Essential protective gear to prevent job site injuries plays a critical role in safeguarding workers from hazards such as impacts, chemical exposures, and falls. According to the U.S. Bureau of Labor Statistics, private industry employers reported 2.6 million nonfatal workplace injuries and illnesses in 2023, a decrease of 8.4% from 2022.

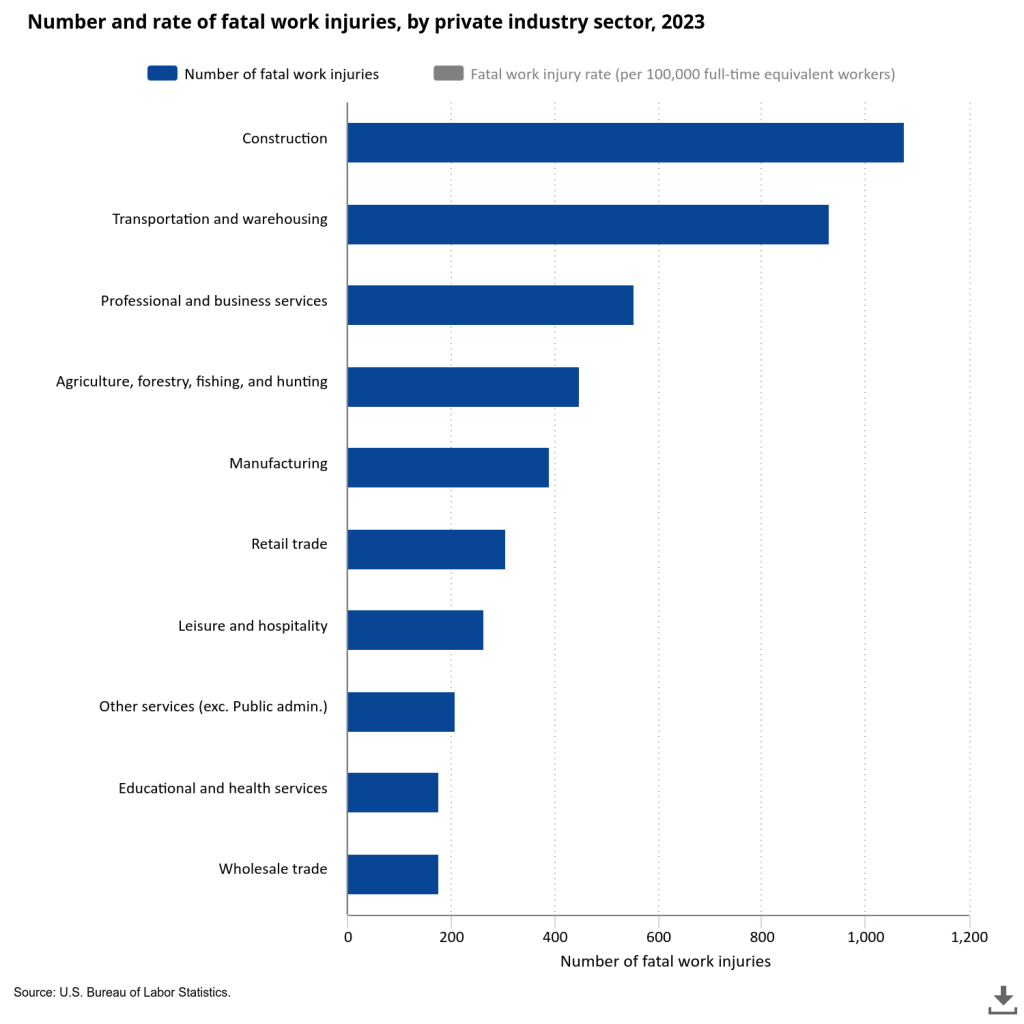

Fatal work injuries totaled 5,283 in 2023, down 3.7% from 5,486 the previous year, with falls, slips, and trips accounting for 885 fatalities.

In manufacturing alone, nonfatal cases dropped from 396,800 in 2022 to 355,800 in 2023, while construction continues to see elevated risks due to heights and heavy machinery.

These statistics underscore the ongoing need for robust safety measures, but they also highlight progress when proper equipment is utilized. Studies show that the proper use of personal protective equipment (PPE) can significantly reduce these risks, preventing serious injuries like burns, fractures, and respiratory issues. For instance, a 2025 study published in Frontiers in Public Health examined how PPE reduces occupational injuries in high-risk industries, finding that consistent use lowers injury rates by up to 60% in scenarios involving hazardous materials or machinery.

At Apollo Safety, we specialize in providing high-quality protective workwear for job sites, helping businesses, governments, and military units mitigate these dangers through reliable products like IRONCAT coated gloves and Moldex N95 respirators. By investing in discounted bundles, organizations can enhance compliance, reduce downtime, and protect their teams effectively.

This guide delves into must-have items, incorporating real-world scenarios from construction and manufacturing to illustrate their importance. We’ll also recommend bundles to encourage seamless adoption.

Head Protection: Essential Protective Gear to Prevent Job Site Injuries

Essential protective gear to prevent job site injuries begins with reliable head protection, which shields against impacts, penetrations, and falling objects common in dynamic environments. Hard hats are indispensable, meeting ANSI Z89.1 standards and requiring regular inspections for cracks or wear. For example, the MSA Polyethylene Slotted Cap Style Hard Hat with Fas-Trac 4-Point Suspension offers cooling vents for comfort in hot conditions (available at Apollo Safety Hard Hat).

Bump caps provide lighter protection for low-risk areas but don’t meet full ANSI standards. In a real-world construction scenario, a government infrastructure project in 2024 saw a worker avoid a severe concussion when a loose beam fell during bridge repairs; their ANSI-rated hard hat absorbed the impact, preventing hospitalization. Similarly, in manufacturing, a military contractor assembling heavy equipment benefited from bump caps in assembly lines, reducing minor head bumps that could lead to lost productivity.

Explore Apollo Safety’s head protection category for bundles including hard hats and accessories at Head Protection, and take advantage of discounted options for bulk government or military purchases.

Eye and Face Protection: Essential Protective Gear to Prevent Job Site Injuries

Essential protective gear to prevent job site injuries extends to eye and face safeguards, defending against debris, chemicals, and intense light. Safety glasses, compliant with ANSI Z87.1, are impact-resistant and ideal for flying particles. The PIP Zenon Z13 Rimless Safety Glasses with Clear Temple and Anti-Scratch Coating provide a wide field of view (shop at Apollo Safety Eyewear).

Goggles offer fuller coverage, fitting over prescription lenses, while face shields add broad protection when paired with glasses. Welding helmets, also ANSI Z87.1-rated, block UV and heat. Consider a manufacturing case where a worker in an automotive plant avoided corneal abrasions from metal shavings thanks to properly fitted goggles during grinding operations. In construction, a military engineering team deploying in dusty environments used face shields during demolition, preventing facial lacerations from exploding concrete.

For comprehensive bundles, visit Safety Glasses: StarLite Clear Lens or BearKat Safety Glasses, and bundle with respirators for discounted protective workwear for job sites.

Respiratory Protection: Essential Protective Gear to Prevent Job Site Injuries

Essential protective gear to prevent job site injuries includes respiratory devices to filter out dust, vapors, and toxic gases. Dust masks, like NIOSH N95-rated ones, handle non-toxic particulates, while respirators address harmful substances and require fit-testing. The Honeywell North Half Mask Air Purifying Respirator ensures a secure fit with silicone construction (available at Apollo Safety Respirator).

Self-Contained Breathing Apparatus (SCBA) supplies clean air in IDLH settings. In a manufacturing real-world example, a chemical plant operator in 2023 averted respiratory distress from solvent fumes using a fit-tested respirator, aligning with the decline in illness cases noted by BLS. Construction scenarios, such as government tunnel projects, highlight SCBA’s role in oxygen-deficient spaces, where a team avoided hypoxia during confined space entry.

Apollo Safety offers the N95 Moldex Disposable Respirators with Exhale Valve for comfort (at Moldex Respirators), and bundle with ANSI-rated safety gloves for savings on face masks and respirators.

Hand Protection: Essential Protective Gear to Prevent Job Site Injuries

Essential protective gear to prevent job site injuries prioritizes hands, vulnerable to cuts, burns, and chemicals. Work gloves vary by task, with options like cut-resistant or heat-resistant varieties. The Portwest Glove with Latex Palm offers premium abrasion resistance (find it at Apollo Safety Gloves).

Gloves with specific protections, such as nitrile for chemicals, enhance safety. In manufacturing, a worker handling sharp sheet metal in an aerospace facility prevented deep lacerations with cut-resistant IRONCAT gloves during a 2024 assembly mishap. Construction teams in military base builds use chemical-resistant gloves to avoid burns from adhesives, reducing injury rates.

Shop Apollo Safety’s hand protection line, including GNDPF-8M Nitrile Disposable Gloves (at Nitrile Gloves), and opt for bundles with high-abrasion IRONCAT options at Hands/Gloves to boost conversions through discounted protective workwear for job sites.

Foot Protection: Essential Protective Gear to Prevent Job Site Injuries

Essential protective gear to prevent job site injuries covers feet with impact and slip resistance. Steel-toed shoes meet ASTM F2413-18 standards for compression hazards. The Tingley Neoprene Snugleg Steel Toe Boot provides durability and traction (available at Apollo Safety Footwear).

Composite-toe shoes offer lighter alternatives, while slip-resistant and waterproof options address wet surfaces. A real-world manufacturing incident involved a forklift operator whose steel-toed boots prevented foot fractures from dropped pallets in a warehouse. In construction, government road crews rely on waterproof shoes to mitigate slips in rainy conditions, aligning with BLS fall statistics. Bundle these with other gear at Apollo Safety for military-grade durability and discounts.

Hearing Protection: Essential Protective Gear to Prevent Job Site Injuries

Essential protective gear to prevent job site injuries safeguards hearing from excessive noise. Earmuffs, meeting ANSI S3.19-1974, block high-decibel sounds and require fit-testing. Earplugs provide portable alternatives for similar protection, such as the 3M EAR Classic Foam Ear Plugs, Uncorded (200 PR/Box), which offer reliable noise reduction with a Noise Reduction Rating (NRR) of 29 dB, ensuring comfort for extended wear in loud environments (available at 3M Ear Plugs).

In noisy manufacturing plants, like those producing military vehicles, earmuffs prevented hearing loss for operators near stamping machines in 2023. Construction sites with heavy equipment see workers using earplugs to avoid tinnitus from prolonged exposure. Explore Apollo Safety’s protective offerings for integrated solutions, bundling these earplugs with respirators for comprehensive noise and dust control in government and military operations.

Reflective Workwear: Essential Protective Gear to Prevent Job Site Injuries

Essential protective gear to prevent job site injuries includes reflective workwear, which enhances visibility in low-light or high-traffic environments to avoid struck-by incidents. High-visibility vests, shirts, and jackets with reflective strips are crucial for workers near vehicles or machinery, meeting ANSI/ISEA 107 standards for fluorescence and retroreflection. In a real-world construction scenario, a government highway crew member avoided a collision with a passing truck during nighttime repairs thanks to a reflective vest that made them visible from afar. Similarly, in manufacturing warehouses with forklift operations, military logistics teams use reflective clothing to prevent accidents in dimly lit areas, contributing to the reduction in transportation-related injuries reported by the BLS in 2023.

For reliable options, explore Apollo Safety’s protective workwear collection, including high-visibility gear, at Protective Workwear and Clothing, and consider bundling with other essentials like gloves for discounted packages tailored to businesses, governments, and military needs.

Additional Considerations: Essential Protective Gear to Prevent Job Site Injuries

Essential protective gear to prevent job site injuries also encompasses clothing and fall protection for holistic safety. Flame-resistant clothing is vital in arc-risk environments, while high-visibility gear prevents vehicle strikes in low-light military or government operations. Fall protection, including harnesses and lanyards, is crucial for elevated work. The DBI-SALA Roofer’s Fall Protection Kit offers complete systems (at Fall Protection Kit).

In a construction scenario, a high-visibility vest saved a worker from a near-miss with moving equipment on a federal highway project. Manufacturing teams use flame-resistant clothing during welding to prevent burns. For fall risks, which caused 885 fatalities in 2023, Apollo Safety’s systems like the Advanced Portable Fall Arrest Post (at Fall Arrest Post) provide anchor points for safe operations. By turning the conversation to mitigation, Apollo Safety’s products directly address these statistics.

Investing in essential protective gear to prevent job site injuries is not just compliance, it’s a strategic move for productivity and well-being. Contact Apollo Safety today for customized bundles, free consultations, and expert guidance tailored to your construction, manufacturing, government, or military needs. Shop now and secure your team’s future.